Mixing Impellers & Dispersion Blades

We offer hundreds of mixing impellers and accessories designed specifically for industrial mixing. Shop low shear propellers, medium shear hydrofoils, high shear dispersion blades and everything in between to match your exact mixing needs. From lab sized to 20"+ diameter impellers, we offer the solution. At Mixer Direct, we take pride in offering one of the best online collections of mixing impellers and accessories in the industry.

Filters

- 1 in. (2)

- 1.5 in. (4)

- 1.6 in. (2)

- 2 in. (9)

- 2.5 in. (8)

- 3 in. (16)

- 3.5 in. (5)

- 4 in. (18)

- 4.5 in. (2)

- 5 in. (14)

- 5.5 in. (1)

- 6 in. (12)

- 7 in. (6)

- 8 in. (12)

- 9 in. (5)

- 10 in. (14)

- 11 in. (5)

- 12 in. (13)

- 13 in. (4)

- 14 in. (14)

- 15 in. (3)

- 16 in. (10)

- 17 in. (1)

- 18 in. (10)

- 20 in. (10)

- 22 in. (10)

- 24 in. (10)

- 26 in. (6)

- 28 in. (5)

- 30 in. (5)

- 32 in. (5)

- 34 in. (5)

- 36 in. (4)

- 38 in. (2)

- 40 in. (2)

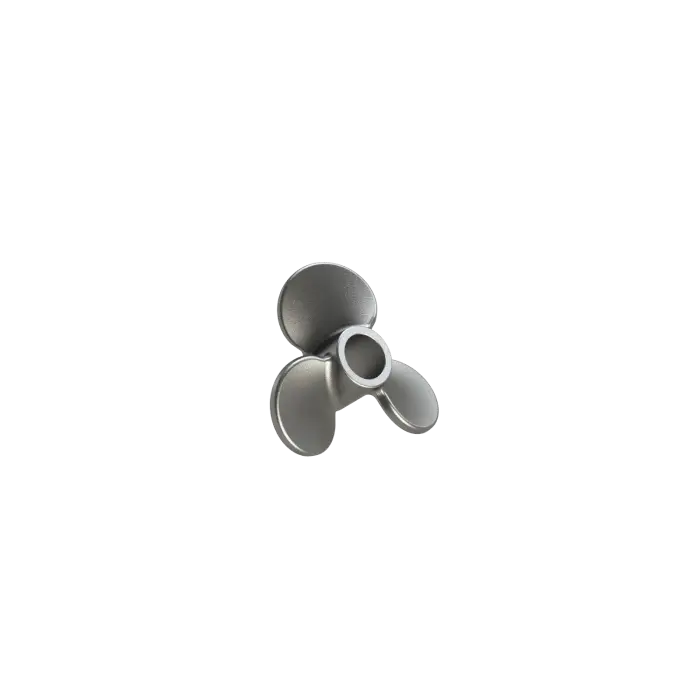

Mixing Propeller

Available in a variety of diameters and bore sizes, our mixing propellers can be sized precisely to match your process requirements. These propelle...

View full detailsUltra Shear Dispersion Blade

Operating at high RPMs, our ultra shear dispersion blades excel in rapidly achieving a fine particle size for solids. As the liquid contacts the...

View full detailsDispersion Blade

Operating at high RPMs, our high shear dispersion blades are designed to efficiently impart solids to a fine particle size. The liquid interacts wi...

View full detailsHydrofoil Impeller

High efficiency hydrofoil impellers are an energy efficient alternative to traditional marine propellers. Hydrofoils offer a higher pumping capacit...

View full detailsLab Sized Mixing Propeller

Designed for use on lab scale mixers and stirrers, these lab sized propellers provide low shear flow in small batch vessels. Constructed of 316 gra...

View full detailsLab Sized Axial Flow Turbine

Designed for use on lab scale mixers and stirrers, these lab sized axial flow turbines provide medium shear in small batch vessels. Very effective ...

View full detailsHigh Flow Dispersion Blade

Operating at high RPMs, our high flow dispersion blades excel in rapidly achieving a fine grind of solids. As the liquid contacts the blades, it...

View full detailsFolding Impeller

Folding impellers allow the use of a large impeller in a closed container due to their unique collapsible blade design. Our 4" and 7" folding impel...

View full detailsLab Sized Hydrofoil Impeller

Designed for use on lab scale mixers and stirrers, these lab sized hydrofoil impellers provide low shear, high flow in small batch vessels. Constru...

View full detailsAxial Flow Turbine

The axial flow turbine is a classic medium shear impeller. This impeller type allows a mixer to break up agglomerations and impart solids effective...

View full detailsRight Hand Mixing Propeller

Available in a variety of diameters and bore sizes, our right handed mixing propellers can be sized precisely to match your process requirements. T...

View full detailsSteep Pitch Mixing Propeller

Available in a variety of diameters and bore sizes, our steep pitch mixing propellers can be sized precisely to match your process requirements. Th...

View full detailsHigh Flow Dispersion Blade with Bolt Pattern

Operating at high RPMs, our high flow dispersion blades excel in rapidly achieving a fine grind of solids. As the liquid contacts the blades, it fl...

View full detailsLab Sized Radial Flow Turbine

Designed for use on lab scale mixers and stirrers, these lab sized radial flow turbines provide medium shear in small batch vessels. The Radial flo...

View full detailsFolding Lab Impeller

Designed to fit into beakers and flasks with narrow necks, our folding lab impeller is the perfect impeller for your laboratory mixing. In the fold...

View full detailsUltra Shear Dispersion Blade with Bolt Pattern

Operating at high RPMs, our ultra shear dispersion blades excel in rapidly achieving a fine particle size for solids. As the liquid contacts the bl...

View full detailsDispersion Blade with Bolt Pattern

Operating at high RPMs, our high shear dispersion blades are designed to efficiently impart solids to a fine particle size. The liquid interacts wi...

View full details10" Lab Anchor Paddle

Our lab anchor impeller is designed for use in a laboratory or small batch setting. The 316SS anchor paddle impeller comes complete with 10" Impell...

View full detailsRadial Flow Turbine

Our radial flow turbine creates a radial flow pattern moving away from the impeller towards the vessel's sides. The flow impacts the side and moves...

View full details5" Lab Anchor Paddle

Our lab anchor impeller is designed for use in a laboratory or small batch setting. The 316SS anchor paddle impeller comes complete with 5" Impelle...

View full details3" Lab Anchor Paddle

Our lab anchor impeller is designed for use in a laboratory or small batch setting. The 316SS anchor paddle impeller comes complete with 3" Impelle...

View full details4" Lab Anchor Paddle

Our lab anchor impeller is designed for use in a laboratory or small batch setting. The 316SS anchor paddle impeller comes complete with 4" Impelle...

View full detailsThree Blade Folding Impeller

Specially designed for mixing in IBC totes, these three bladed folding impellers offer medium shear mixing solutions in numerous applications. This...

View full details2" Lab Anchor Paddle

Our lab anchor impeller is designed for use in a laboratory or small batch setting. The 316SS anchor paddle impeller comes complete with 2" Impelle...

View full details